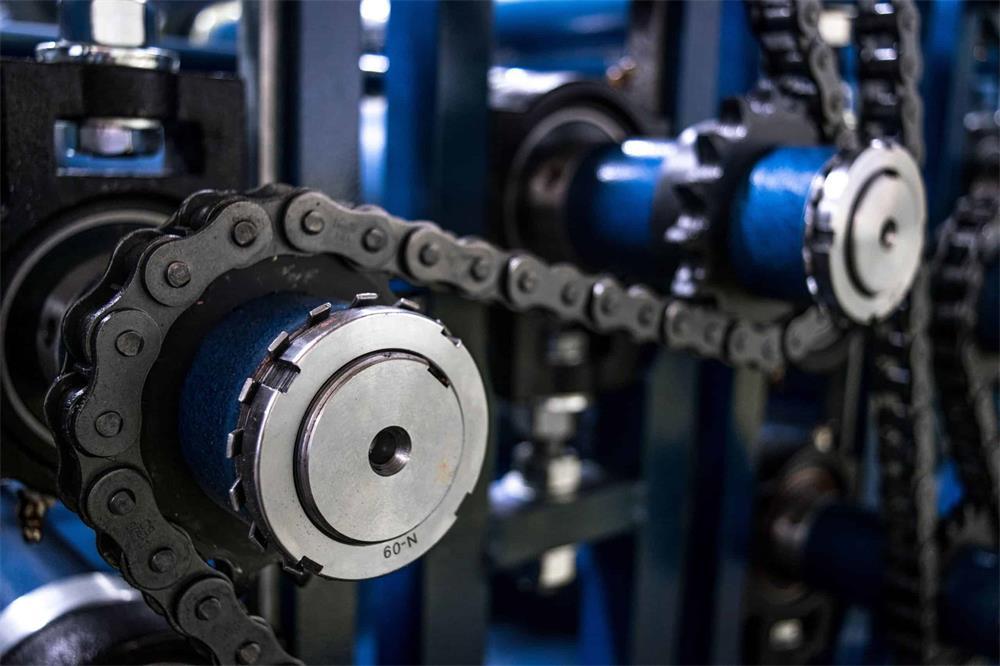

What Are the Different Types of Roller Chains?

A roller chain is a kind of chain used to transmit mechanical power. It is a type of chain drive and is widely used in household, industrial and agricultural machinery. Roller chains have many types and specifications, and there are also great differences in characteristics and applications. We can learn more about roller chain products by understanding the characteristics of the following different roller chains.

Side bend chain

Side-bending chains are often used as conveyor chains or drag chains in applications that require curved tracks. The chain runs around various curves with different radii. The reduced pin diameter allows these chains to bend, but tapered pins or double tapered sleeves can also be used.

Since the conventional application of these chains allows the use of low-viscosity oil for initial lubrication, only a small amount of oil film remains on the surface.

O-ring roller chain

The O-ring chain was originally developed as a transmission chain for motorcycles, but the technology is also used in standard industrial chains. The initial lubricant is applied to the chain bearing using a vacuum process and then sealed with an O-ring. This combination of lubrication and sealing means that these chains do not require further lubrication throughout their life cycle and can therefore be classified as "low maintenance" chains.

Industry application

(1) Agricultural machinery

(2) General engineering and system construction

(3) Bulk goods manufacturing

(4) Construction machinery industry

(5) Construction technology

Double pitch roller chain

Take the single-pitch chain manufactured according to ISO 606 as the benchmark; except for the pitch, the size of the chain meets the same standard parameter requirements of the corresponding single-pitch product.

Unlike single-pitch chains manufactured according to the ISO 606 standard, double-pitch chains are designed for applications with lower speed and power transmission requirements.

The main difference is that the chainplate of the double-pitch roller chain is twice the length of the chainplate installed in the standard roller chain, as the name indicates.

In addition to the above aspects, the chain product series manufactured in accordance with American standards includes products with normal thickness chainplates or thicker chainplates, as well as some modified models that use smaller or larger rollers. Double-pitch hollow pin roller chains are usually only provided with straight chainplates or supplied as bushing chains or roller chains.

One of the major advantages of the said product is that the pitch is longer, the conveyor roller can be installed, and the friction and the internal tension of the chain can be significantly reduced in many applications.

Industry application

(1) Conveying technology

(2) General engineering and factory construction

(3) Agricultural machinery

(4) Food industry

(5) Sorting equipment

If you want to know more about roller chains after reading the above, you can get a comprehensive solution by contacting us.

As an experienced quality chain supplier, ZMIE has become a leader in the industry with its excellent manufacturing technology and considerate service, and many customers choose ZMIE for this reason. We are equipped with a professional production team and a strict quality inspection system to fully control the quality of our products. In addition, we can also provide a thoughtful one-stop service according to the needs of users. If you want to buy our roller chain, please contact us immediately!